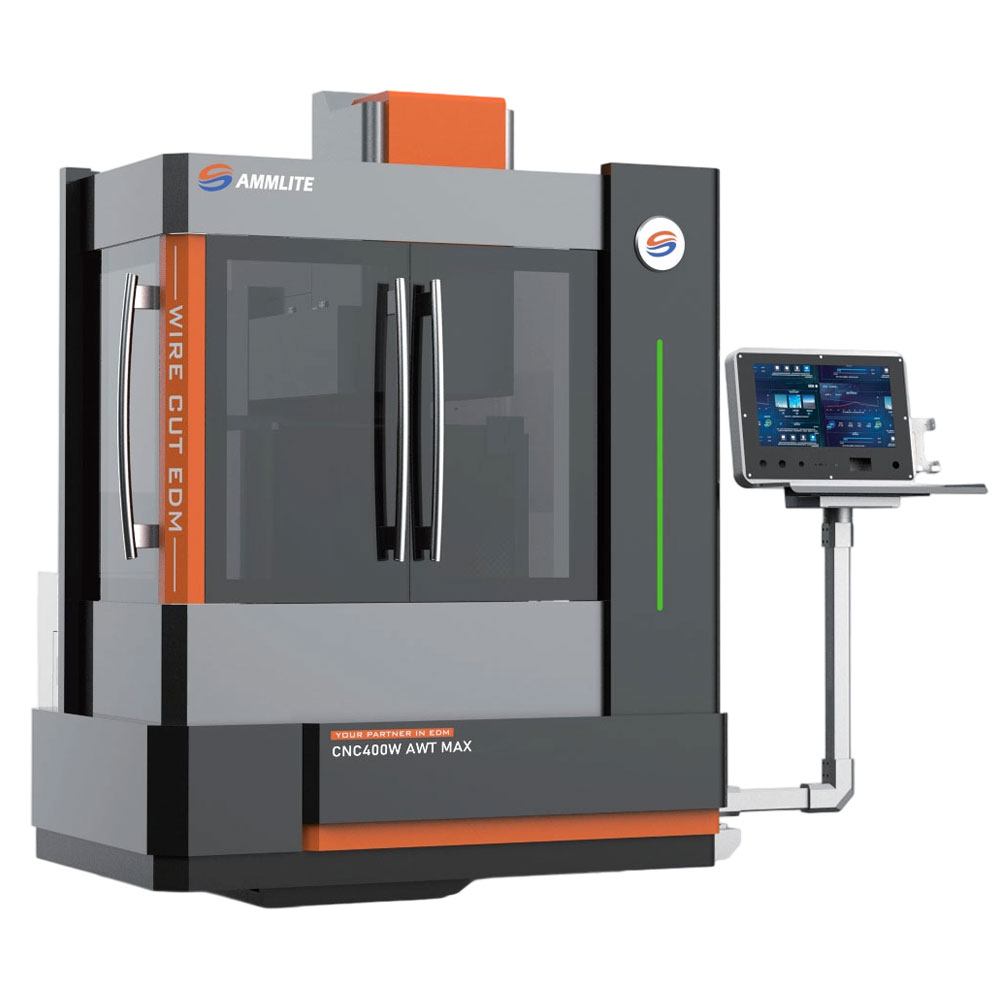

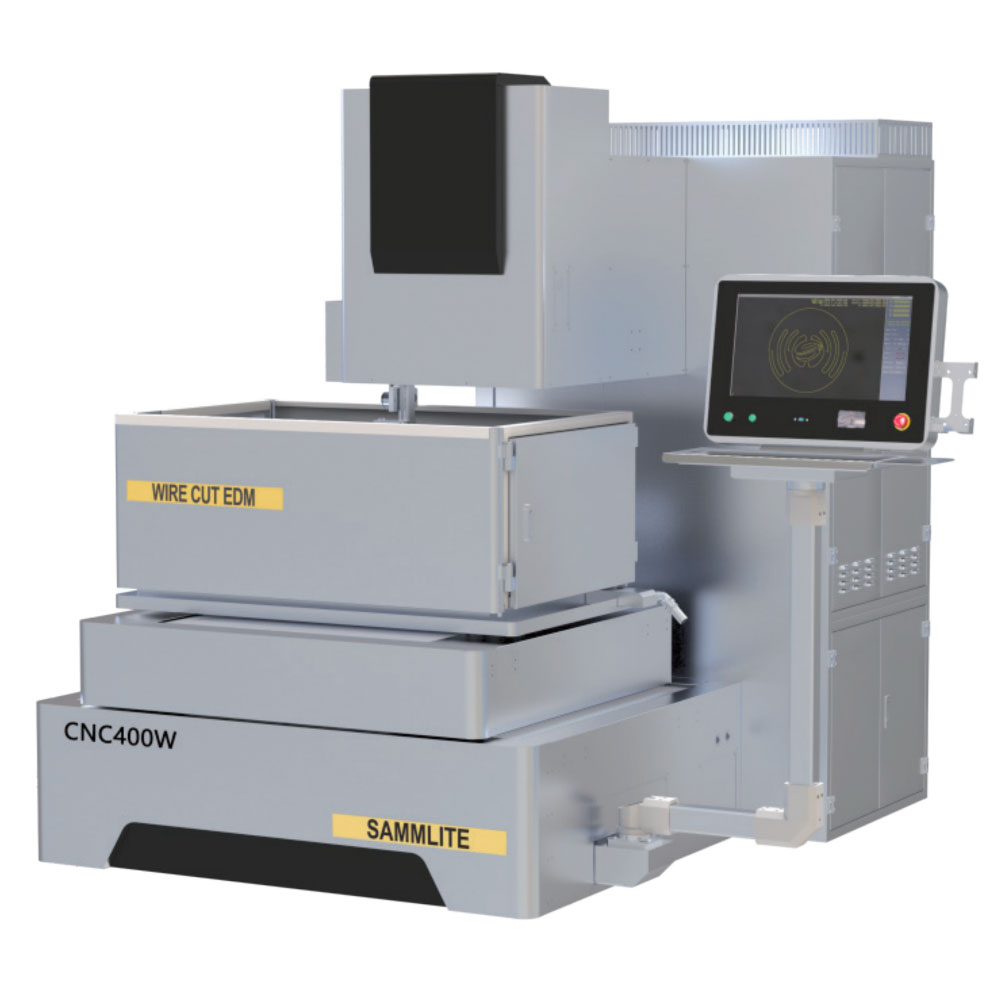

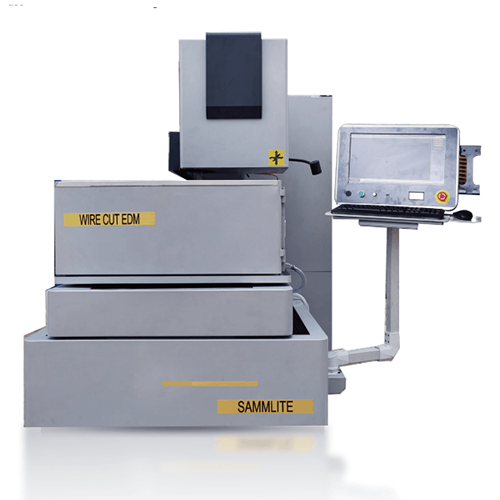

Wire Cut EDM CNC400W AWT/CNC400W AWT MAX

Description

Technical Specification

Our automatic wire threading wire cutting machine features intelligent auto-threading technology that significantly reduces labor costs and improves operational efficiency. Built with premium brand-name components, this reliable system ensures consistent performance and minimal downtime. The automated wire threading eliminates manual intervention, allowing for continuous operation with superior cutting precision.

| Machine | CNC400W AWT MAX | CNC400W AWT |

|---|---|---|

| Table Size(mm) | 900×600 | 800×500 |

| Table Travel (mm) | 480×380 | 480×400 |

| Max Thickness(mm) | 190 | 190 |

| U/V Axis Travel(mm) | 70×70 | 35×35 |

| Taper(degree) | ±3° | ±3° |

| Max Load (kg) | 500 | 500 |

| Wire Diameters(mm) | 0.18 | 0.18 |

| Accuracy(mm) | ±0.005 | ±0.005 |

| Dimension(mm) | 1800×2200×2200 | 1800×2200×2200 |

| Weight(Kg) | 1900 | 1900 |

| Generator | ||

|---|---|---|

| Roughness | Ra<1.0 | Ra<1.0 |

| Efficiency(mm²/min) | 100-200 | 100-200 |

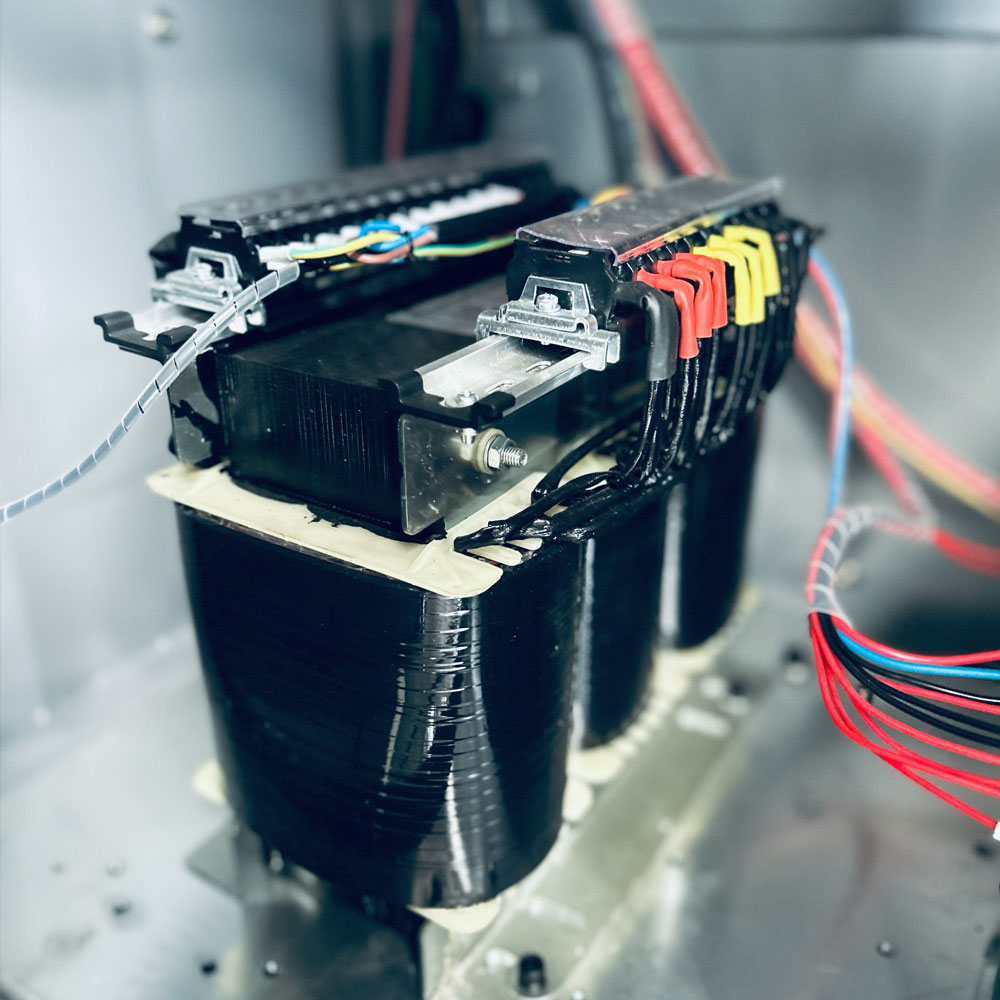

| Power | 4KWA50/60HZ 220V/380V | 4KWA50/60HZ 220V/380V |

| U/V/Z Axis Motor | Subdivision Motor | Step Motor |

| X/Y Motor | Panasonic Servo Motor | Panasonic Servo Motor |

| Wire Motor | Servo Motor | Servo Motor |

| System | ||

|---|---|---|

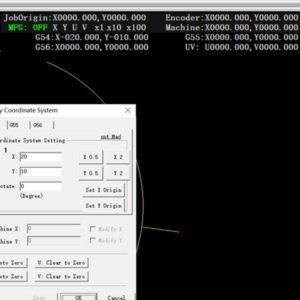

| Software | AutocutV10.1&NCCAD | AutocutV10.1&NCCAD |

| Windows | Win10 | Win10 |

| Hardware | Industrial PC,32G SSD | Industrial PC,32G SSD |

| NC Axis | 5 Axis NC Control | 5 Axis NC Control |

| Language | ENG/CHN | ENG/CHN |

AWT Option

| Hole Diameter | <0.5-2.0mm or>4.0mm | Flate/Slope Sensor Function | √ |

|---|---|---|---|

| Max Height of Threading | Hole:0.5-2.0mm/150mm | Wastes Drop Function | √ |

| Max Height of Threading | Hole:4.0/less than 80mm | Tension Control | √ |

| Max Height of Wastes Drop | <50mm | Tube Air Clean Function | √ |

| Threading Time | 30-45sec | Liquid Clean Function | √ (WD-40) |

| Max Workpiece Height | 190mm | Wire Broken Sensor | √ |

| Air Pressure | >0.4MPA | Semi-Auto Threading | √ |

| Power Consumption of AWT | 2KWA | Software | AutocutV10.1 AWT |

| Drum Control | 1.5KWA Servo Motor | Max Threading Hole each time | 150 Times |

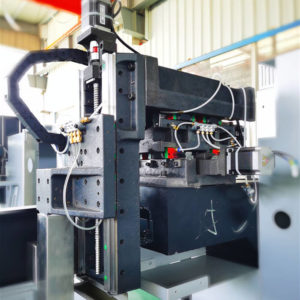

Scientific Design of Z/U/V Structure

The Z/U/V axises use ball screw and linear guide to achieve high precision. It suits taper cutting prefectly and allows users to have better operating experience.

Space Saving Design Only 3m²

X-axis and Y-axis are table movement structure. 5 axis CNC Wire Cut EDM machine adopts HT250 castings, which has a compact and beautiful structure. Occupied area 3m².

Z Axis NC Control

Z Axis has position memory function, easeir for taper operating.

X/Y/U/V NC Control

X/Y/U/V feedback to the wire EDM system.

Applications

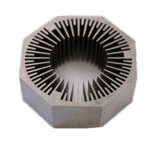

| Material | DC53 |

| Thickness | 30mm |

| Cuts | 3 cuts |

| Hours | 6 hours |

| Ra | 0.95 um |

| Material | CR12 |

| Thickness | 210mm |

| Cuts | 3 cuts |

| Hours | 2 hours |

| Ra | 1.5 um |

| Material | H13 |

| Thickness | 42mm |

| Cuts | 2 cuts |

| Hours | 3 hours |

| Accuracy | 0.01mm |

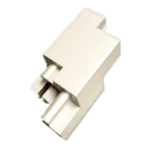

| Material | CR12 |

| Thickness | 40mm |

| Cuts | 3 cuts |

| Hours | 40 min |

| Accuracy | 0.008mm |

Videos

Accuracy Measurement of Wire Cut EDM Workpieces

High Speed Cutting Demonstration

Wire Cut EDM AutoCut Tutorial

recently added Products

Wire Cut EDM CNC500W / CNC630W

Die Sinking EDM CNC300 / CNC350

CNC DIE SINKER CNC 400 / CNC450

Reviews

There are no reviews yet.